We don’t know what car brand you got, but we are sure about, that you want extend service life as much it is possible. Car is like a human body, where everything is works together, while heart is beating. And heart of car, is of course engine. Before we will discuss, how to decrease wear of engine, we need to understand how it is happening.

Dmitrii Garkunov in “Tribotechnic” book describes wear mechanism of metal surfaces and other types of wear.

Let’s highlight main ones:

- Wear of metal rubbing surfaces – this mix of abrasion and crumpling. Abrasion- separation or cutting of metal particles with subsequent removal. Crumpling- changing the linear dimensions of the part without loss of mass, due to flattening.

- There are 3 types of wear processes, in same time: interaction of friction surfaces, changes occurring in the surface layer of the metal, and the destruction of surfaces.

There are two types of interaction between surfaces:

- Mechanical – mutual engagement and embedding of sliding surfaces.

- Molecular – sticking and gripping of surfaces with breakout. It is unavoidable when the oil film is destroyed.

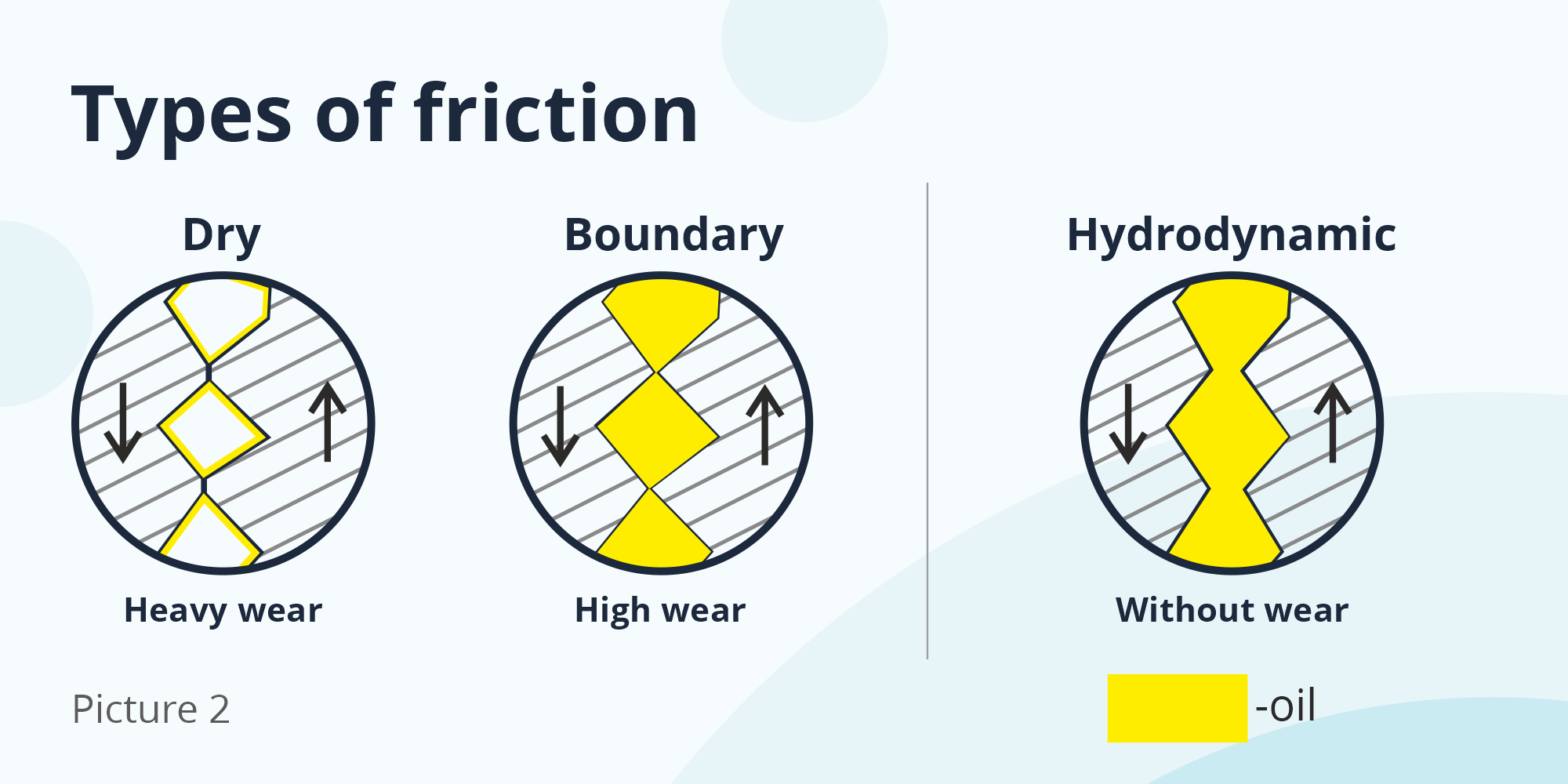

There are 3 types of frictions:

- Dry friction (without lubricity) Leads to very rapid wear and tear

- Boundary friction

- Hydrodynamic friction

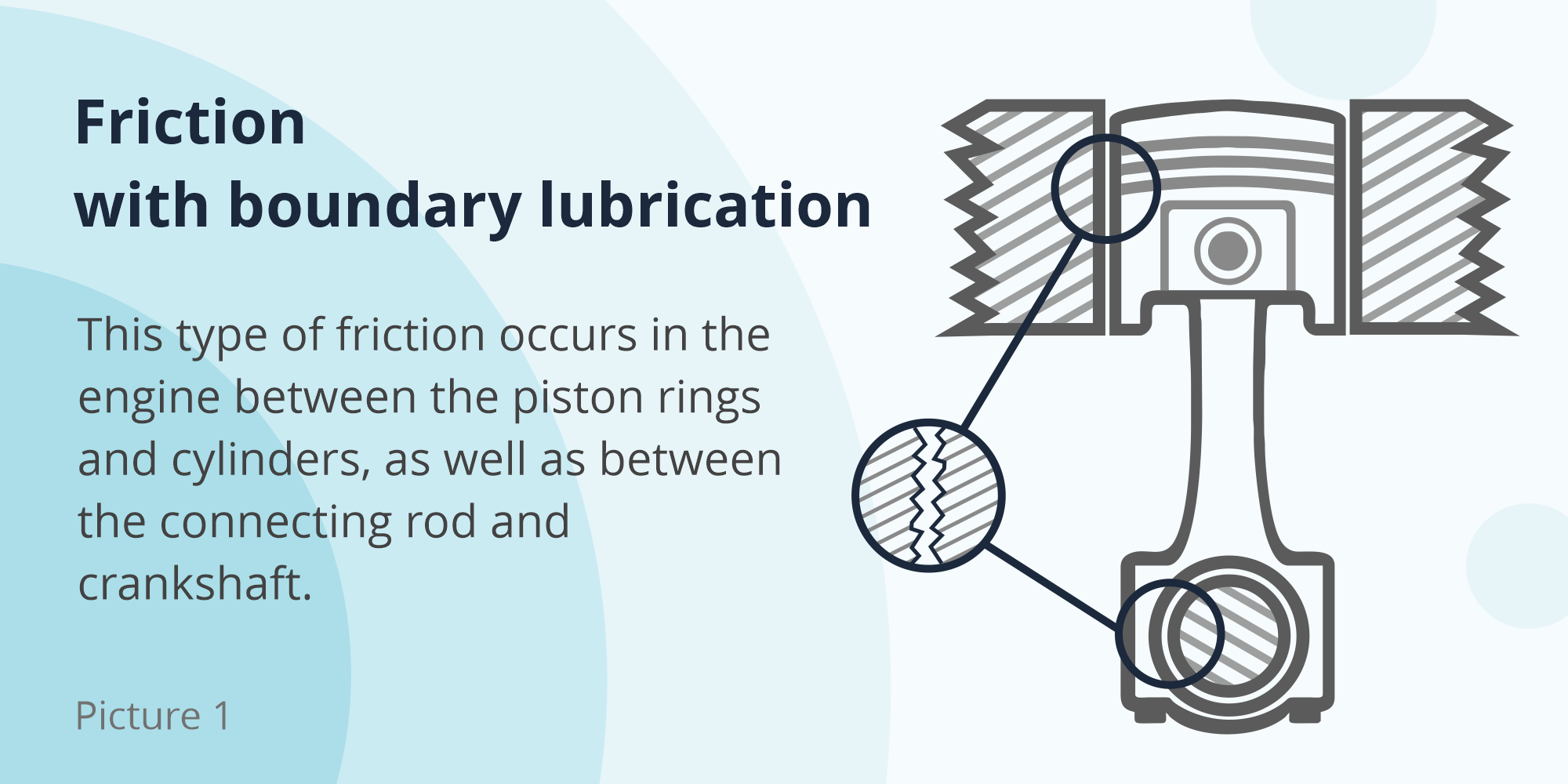

The oil film located between the parts, of course, reduces the friction force and reduces the wear of the rubbing surfaces, but it does not completely stop it. Why? It is simply very small. This type of friction occurs in the engine between the rings and cylinders.

Such friction is possible between the crankshaft or camshaft necks and the liners when the oil is applied under pressure. The rubbing surfaces do not wear out, because they are completely separated by a layer of grease.

Of course, not only friction destroys surface of engine. There are also hydrogen and abrasive wear, oxidative and corrosion-mechanical wear. We need to mention more about hydrogen wear. How it is happening?

Atomic hydrogen is released from any oil and fuel and penetrates the subsurface layer of the metal. There, it turns into a molecular gas, creating pressure that destroys the rubbing surface from the inside. At some point, it just becomes a powder and is carried away by the oil. This process, alas, is continuous.

So, how to protect “heart” of car?

We need to say: there no miracle-advise, how to make “heart of car” work for years. On any car forum, you can see “home-experts” who will tell you: “Change oil more, and there will be no problems!”

Undoubtedly, oil change is important, as well as timely, regular maintenance. But as we found out above, often the oil itself contributes to hydrogen wear, which means they cannot do alone. It is for this case that anti-wear additives were invented.

When they are added to the fuel, a strong tribological film is formed on the surface of the working parts of various mechanisms, which minimizes wear and helps protect the metal from caustic acids. The film consists of products of mechano-chemical transformations of the additive on the metal surface. The way it is formed depends on the friction mode. For research purposes, more than ten different methods are used to evaluate lubricating properties based on the following indicators: the coefficient of friction, the average diameter of the wear spot, and the critical load before jamming.

In addition, anti-wear additives increase the operating life of the engine, bring the fuel performance to meet the relevant regulatory requirements, additionally protect the fuel system elements from corrosion and, as a result, reduce the cost of routine maintenance. The certified lubricant additive does not affect other indicators of diesel fuel — fluidity, color, etc., and its use and storage does not require special equipment.

Anti-wear additive of new generation:

Wear and tear of fuel equipment parts is a sore subject for owners of vehicles with a diesel engine. We have studied this problem in detail and developed an anti-wear (lubricating) additive "Molecule", which is a mixture of fatty carboxylic acids in a hydrocarbon solvent. It is intended directly for low-sulfur diesel fuels that have been hydro treated.

The introduction of "Molecule" into the fuel at a concentration of 200 ppm improves the lubricating properties by 40-50 %, and the diameter of the wear spot is reduced from 550 to 370-330 microns. But, be careful, the use of this additive requires a certain temperature regime: for more effective interaction, it is necessary to heat both the additive itself and the fuel to 40-50 degrees.

It is important to mention another important feature of all anti-wear additives, including "Molecule". In the presence of other additives in the fuel, for example, depressant-dispersing or cetane-increasing, the working concentrations of which are an order of magnitude higher, there is competition for the surface of additives. And anti-wear, alas, are inferior. In this case, they should be introduced into diesel in greater concentration.

The additive is a real, effective way to minimize wear and tear, so that the heart of your car works as long as possible and without interruptions!